Introducing the all new Electric Brewing Supply Nano Brewer Touch Screen brewery control solution, the 360 Series. The only product available designed for split vessel brew systems, with more features added regularly.

This particular controller is designed for controlling 2 15kw elements at the same time for brewing in 2 separate vessels or one larger one. This controller software allows the simultaneous heating of a HLT while also heating the Boil kettle. 3 phase panels also have the ability to negate the frequently failing solid state relays for a more traditional hysteresis approach if the need such arise.

Average lead time is 2-3 weeks

30-90 gallons 3-7 bbl

Panel Specifications

| 360 Controller Screen |

4.3" Standard controller, upgrade to 7" available

|

| Full load amperage: |

88 amps @ 208v 3 phase

Full load is via split disconnect feed.

|

|

Max Output:

|

(2) 15000w Elements (208v/3ph) and (2) Brewery Pumps @ 2 amps |

| Power outlet: |

Power via cable and cable gland, no outlet supplied |

| Power cord: |

2x 6/4 SOOW Cables recommended |

| Power in: |

Power via cable gland or conduit

208v with ground and neutral.

Panel uses and provides 120v for control and for pumps

International, 220v variance available

|

| Panel outputs: |

(2) Holes for conduit or cord grips for elements

(2) Neutrik 120v Power-Con outlets for pumps

(4) Neutrik 120v Power-Con outlets for fermentation/valves

|

| Panel inputs: |

(4) XLR inputs with M12 variant cables for NPT and TC probes

(1) Cat5 network port for net communications

(1) Cat5 Cscan expansion communications port

(2) M12 Connectors for flow meters

|

| Input probe type: |

RTD / PT100 |

| Included in the box: |

(1) Control Panel

(3) Temp probe cables

(X) Temp probes dependent on selection

|

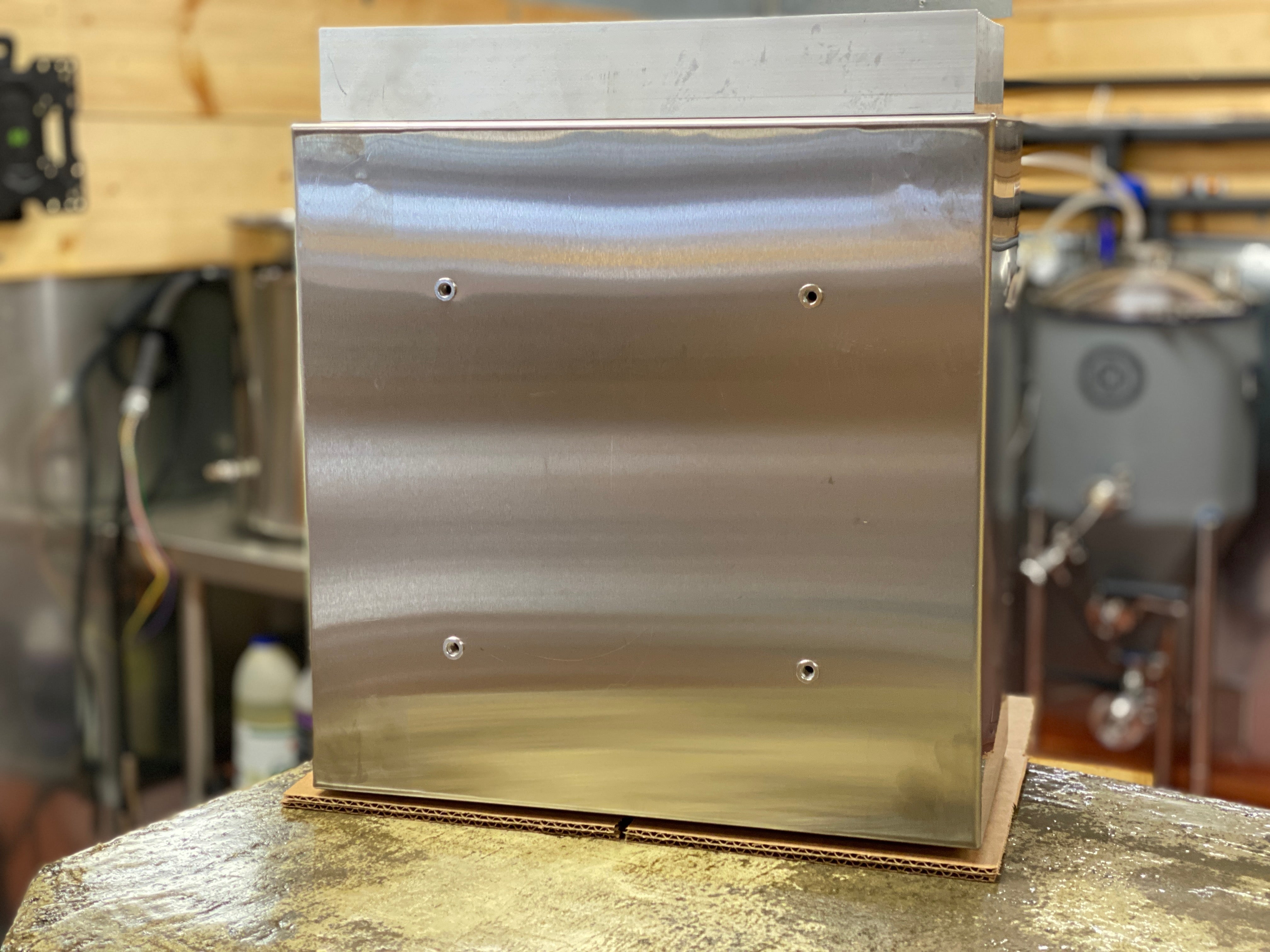

| Enclosure: |

Stainless Steel Nema 4x Enclosure

20 in (W) x 22 in (H) x 8.5 in (D)

500mm x 550mm x 225mm

|

| Certifications: |

Certified UL and cUL |

| Point of origin: |

Enclosure from Ohio, USA

Touch control from Indianapolis, IN, USA

Inlet and Connector from USA

Terminal blocks, relays and power from Germany

Contactors and Breakers from EU

Outlets and SSRs from China

|

| Warranty: |

1 year parts, 90 days labor |

All panels are assembled by Electric Brewing Supply, in Chassell, Michigan from globally sourced parts.

360 Series

The all new Electric Brewing Supply 360 Series brewery control solutions. Based on a standard 4-inch touch screen controller. With solutions available for home to commercial; gas, steam, and electric brewing, from 5-gallon BIAB to 15bbl Steam. Intercommunication between brewhouse and cellar control; as well as keg washing. The avid brewer or the startup nano-brewer, we've created a solution (or can) that fits your needs today and can add on to into the future. The only solution available for home brewing or commercial brewing alike. Available in low cost non-UL and commercial friendly UL (even Canadian friendly cUL) variations. All controls will feature local touch control, while the brewing and fermentation panels will also have a unique web experience.

Touch Control

Our 360 Series touch control systems are all based on controllers made by Horner Automation out of Indianapolis, Indiana. This means our controllers are made for industry and tested to break. The units are UL listed, as well, meaning they gone through 3rd party certification to insure the performance. Not to be left out, the screen is rated IP65 and Nema4x; meaning it can take the wet brewing environment and spit it back. With this, we hope you have some peace of mind.

Opportunity in design

Because our systems are based on Horner's controllers, this means the capabilities of our systems exceed our own base designs; giving you a valuable tool to expand and grow with. With each major revision of our code, new features are intended to help you more. With time, new expansion options in the form of valve control panels, VFDs for commercial, and more are a possibility without the expense of it all up front. No longer do you buy the Semi truck when you only need the pickup truck.

Easy to use interface

Our latest revisions to the 360 line have one goal in mind; to simplify the process while providing the most opportunity at your fingertips. By way of easy element output selection users can set a temp, select their elements and have peace of mind in knowing what they choose is what is heating. This extends to all our systems, including direct fire or flame as well as steam systems. Through our years of experience working with home brewers and startup commercial brewers we have a solid understanding of what we feel the user expects in their setup. While having all the features can't hurt, if you can't use them, then why are you buying them?

Options for all

The greatest opportunity for options comes with our 360 series solutions. This is because of the universally capable controllers and the code we've developed. No longer are you limited to just an electric brewery from Electric Brewing Supply, you have the opportunity for gas, direct fire, and steam setups depending on the needs of your brewery. This carries to size as well, from the smallest 10-gallon system to the full scale 15bbl brewhouse or even 120bbl fermentation vessels. We've tested through the scales to find what fits, and if we don't have it today, it doesn't mean we can't offer you a solution.

4.3 Inch, 7 Inch, or bigger

Perhaps our favorite part about the 360 series is the options. No longer are you locked into just a computer screen or just the tiny led screen. The 360 controls are all based on a 4.3" screen, that can be upgraded to 7". The screen gives you a physical point to control your brewery, without need of a computer and without worry of broken LEDs or switches. To top it all off, the unit can go bigger by way of any internet enabled device, say a 10" tablet. With all the power of the touch screen, your web page access gives you the ability to control and monitor by remote, whether in the same room or in another part of the brewery or even off site* such as from home.

Intercommunication

The Electric Brewing Supply 360 Series brewery control solutions offered the benefit of inter communication. What we mean by this is that each controller can talk to others, but how we implement them is a benefit to the small brewer. With the brewery controller in front, one can check fermentation as well as keg washing progress. The smaller panels can even directly control some fermentation from the brewhouse. By way of your network, the brewer can keep tabs while focusing on the part of the process that takes the most time and at points, most attention; the brewing.

Probe Specifications

| NPT Style Probe

|

Tri-Clamp Style Probe

|

NPT Are also available in 4 and 8 inch lengths

Tri-Clamp are also available in a 7 inch length

Accessories

|

Assembled Tri-Clamp Element for heating

Available starting at $190 Each

Shop for now

|

|

Power Con to 5-15 jumper cables

Recommended for between the pump and your panel. As well as for between your fermentation heat and cooling devices.

Available for $15 each

Shop for now

|